Customized LM80 2835 0.6W SMD LED chip manufactured in China

Product Description

Features of SMD led Chip:

1.Silvering of bracket ≥100u, the reflector surface is clean and smooth vith uniform and brightness

2.LM 80 test: small lumen depreciation , 3000hour<1%

3.Consistent:light , wave, angel , color is consistent .

4.120°No Chip color bias

5.Pass the lead-free reflow soldering .it's suit to the automatic SMT.

6.Heat& electric seperation design , good heat dissipation .

s suit to the automatic SMT.

6.Heat& electric seperation design , good heat dissipation .

| High Voltages series |

| Item | Voltage | Current | Color Temperature | Lumen | Ra |

| (V) | (mA) | lm |

| 2835 0.6W | 9-11 | 60 | 2800-3200K/4000K-4500K/5500-6500K | 70-80 | |

Our Services

1.For all your inquires about us or our product ,We will reply you indetails with 24hours.

2.We offer OEM service,Your own logo can be printed on the products .for the packing we also can customize the retail box packing.

3.Three years warranty.

4.After sale service : During the warranty time , all the problems caused by our products quality .we will 100% responsible for you ,remake the products for you freely togerther with next order.

Packaging & Shipping

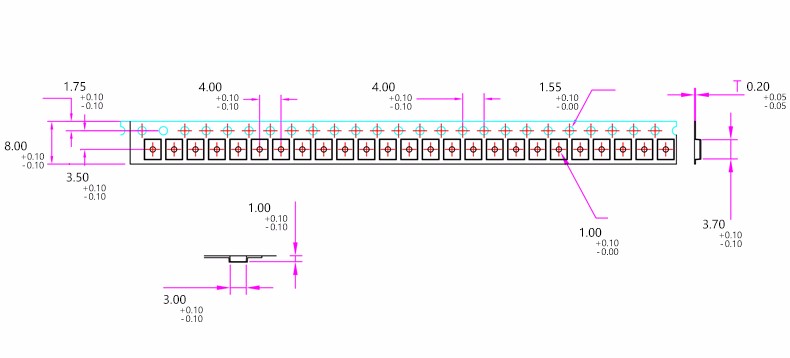

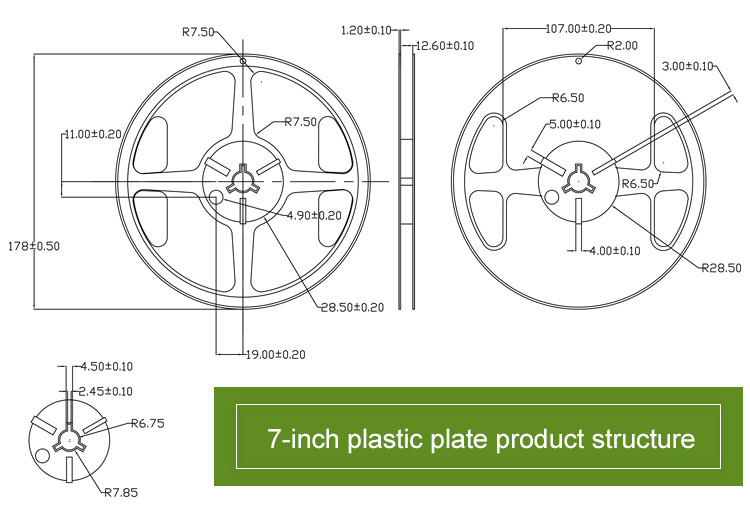

Product parameters:

1.10 sprocket hole pitch cumulative tolerace ±0.20mm.

2.Carrier camber not to exceed 1mm in 100mm.

3.A0 and B0 measured on a plane 0.3mm above the bottom of the pocket.

4.K0 measured on a plane on the inside bottom of the pocket to the top surface of the carrier.

5.Angle is not marked:3°.

6.All dimensions meet EIA-481-D requirements.

7.Material:Black Polystyrene.

8.Packing length per 7"reel:M/R.

9.Component load per7"reel:PCS.

Cautions:1.Storage Before opening the package:The LEDs should be kept at 5~30°C and 60%RH or less. The LEDs should be used within a year. After opening the package:The LED must be used within 24 hours, else should be kept at 5~30℃ and 30% RH or less. The LEDs should be used within 7days after opening the package. If unused LEDs remain, they should be stored in moisture proof pachages .recommend to return the LEDs to the original moisture proof bag and to reseal the moisture proof bag again. If the LEDs have exceeded the storage time, baking treatment

Cautions:1.Storage Before opening the package:The LEDs should be kept at 5~30°C and 60%RH or less. The LEDs should be used within a year. After opening the package:The LED must be used within 24 hours, else should be kept at 5~30℃ and 30% RH or less. The LEDs should be used within 7days after opening the package. If unused LEDs remain, they should be stored in moisture proof pachages .recommend to return the LEDs to the original moisture proof bag and to reseal the moisture proof bag again. If the LEDs have exceeded the storage time, baking treatment

should be performed more than 24 hours at 60 ± 5°C.

2.Soldering Iron

When hand soldering, keep the temperature of iron below less 300℃ less than 3 seconds

The hand solder should be done only one times

3.Repairing

Repair should not be done after the LEDs have been soldered. When repairing is unavoidable, a double-head soldering iron should be used (as below figure). It should be confirmed in advance whether the characteristics of LEDs will or will not be damaged by repairing.

Handling Precautions:

1.Compare to epoxy encapsulant that is hard and brittle, silicone is softer and flexible. Although its characteristic significantly reduces thermal stress, it is more prone to damage by external mechanical force . As a result, Special handling precautions must be observed during assembling using silicone encapsulated LED products, Failure to comply might leads to damage and premature failure of the LED.

2.Handle the component along the side surface by using forceps or appropriate tools; do not directly touch or Handle the silicone lens surface, it may damage the internal circuitry.

3.The outer diameter of the SMD pickup nozzle should not exceed the size of the LED to

prevent air leaks. The inner diameter of the nozzle should be as large as possible. A pliable

material is suggested for the nozzle tip to avoid scratching or damaging the LED surface during

pickup. The dimensions of the component must be accurately programmed in the pick-and-place machine to insure precise pickup and avoid damage during production.

4.Do not stack together assembled PCBs containing LEDs.Impact may scratch the silicone lens or damage the internal circuitry.

5.Not suitable to operate in acidic erivironmengt.PH<7.

FAQ

1: How to deal with the faulty?

A: Firstly, Our products are produced in strict quality control system and the defective rate will be less than 0.02%.

Secondly, during the guarantee period, we will send new lights with new order for small quantity. For defective batch products, we will repair them and resend them to you or we can discuss the solution including re-call according to real situation.

2: Do you have discount for your products?

A:Discount will be offered according to order quantities.

3: Are you a manufacturer:

A: Yes, Pusisat has over 12 years' experience in LED lighting industry.

4:Can I have a sample order for led light?

A: Yes, we welcome sample order to test and check quality. One sample or mixed samples are acceptable.

5: Can I add my logo on the products?

A: Yes, OEM and ODM are available for us.

6: Can I have a visit to your factory before the order?

A: Sure, welcome to visit our factory.

7: How about delivery time of the order?

A: 7-20 days after getting deposit.

8: How about payment terms?

A: 30% deposit, the rest payment balance before shipment.

9: Can I use payapl for sample?

A: Sure. Paypal, WU, TT are available.

10: What is the warranty for china led light ?

A: china led light warranty is 2 years warranty. Any damaged in transporation or any quality issue, we will provide the new one to customer.

11: When can i get price?

A: Usually quote within 24 hours after we get your inquiry.

12: Can we design packing?

A: Yes,we also can design customer's own packing.

13: How do you ship sample?

A: We usually ship sample by DHL,UPS,Fedex.

14. Can you supply the special lighting design?

A:Sure, LED lighting design including the Dialux simunlation,3D products renderings etc.